To choose a CAD model you must first identify the force and speed closest to your application requirements.

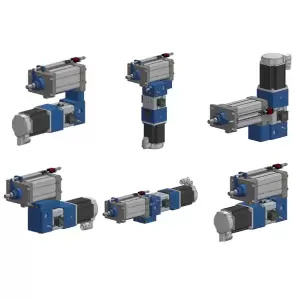

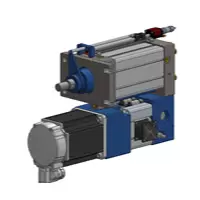

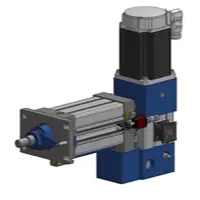

S-Series Actuator Only Specifications and CAD Models:

Series / Model Number Alpha-Numeric Designation: SxxCyy-zz-D

First letter: designates the product series

- S-Series

- P-Series

- H-Series

xx: designates the motor size – for example

- S06 is a 60mm motor

- S14 is a 142mm motor

- S19 is a 190mm motor

Cyy: designates the cylinder size – for example

- C10 is a 1in cylinder

- C32 is a 3.25in cylinder

- C60 is a 6in cylinder

zz: designates the pump size which correlates to flow/speed

-D: If model name ends in -D designates DC version. If model name does not end in -D designates AC version

| Series No. | Input Voltage | Extend Force (lbf) | Retract Force (lbf) | Extend Speed (in/s) | Retract Speed (in/s) | Max Cylinder Capacity Extend (lbf) | Max Cylinder Capacity Retract (lbf) | Max Input Torque (in-lbs) | Max Input Speed (rpm) | Max Motor Square Frame Size (in) | Max Motor Shaft Dia (in) | Model Name |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Click on the link below to download | ||||||||||||

| S0ZC10-02 | Actuator Only | 2356 | 1435 | 0.84 | 1.38 | 2356 | 1436 | 9.68 | 8000 | 3.74 | 0.748 | S0ZC10-13 |

| S0ZC10-05 | Actuator Only | 2356 | 1435 | 1.96 | 3.21 | 2356 | 1436 | 22.59 | 8000 | 3.74 | 0.748 | S0ZC10-13 |

| S0ZC10-07 | Actuator Only | 2356 | 1435 | 3.22 | 5.28 | 2356 | 1436 | 37.12 | 5000 | 3.74 | 0.748 | S0ZC10-13 |

| S0ZC10-11 | Actuator Only | 2356 | 1435 | 5.17 | 8.49 | 2356 | 1436 | 59.71 | 5000 | 3.74 | 0.748 | S0ZC10-13 |

| S0ZC10-13 | Actuator Only | 2040 | 1243 | 7.97 | 13.08 | 2356 | 1436 | 79.66 | 5000 | 3.74 | 0.748 | S0ZC10-13 |

| S0ZC10-21 | Actuator Only | 2356 | 1435 | 9.09 | 14.92 | 2356 | 1436 | 104.89 | 5000 | 7.48 | 1.496 | S0ZC10-36 |

| S0ZC10-23 | Actuator Only | 2356 | 1435 | 10.91 | 17.9 | 2356 | 1436 | 125.87 | 5000 | 7.48 | 1.496 | S0ZC10-36 |

| S0ZC10-27 | Actuator Only | 2356 | 1435 | 14.55 | 23.87 | 2356 | 1436 | 167.83 | 5000 | 7.48 | 1.496 | S0ZC10-36 |

| S0ZC10-31 | Actuator Only | 2356 | 1435 | 20.45 | 33.57 | 2356 | 1436 | 236.01 | 4000 | 7.48 | 1.496 | S0ZC10-36 |

| S0ZC10-34 | Actuator Only | 2356 | 1435 | 26.36 | 43.26 | 2356 | 1436 | 304.19 | 4000 | 7.48 | 1.496 | S0ZC10-36 |

| S0ZC10-36 | Actuator Only | 1988 | 1211 | 34.54 | 56.69 | 2356 | 1436 | 336.33 | 3000 | 7.48 | 1.496 | S0ZC10-36 |

| S0ZC15-02 | Actuator Only | 5301 | 2945 | 0.37 | 0.67 | 5301 | 2945 | 9.68 | 8000 | 3.74 | 0.748 | S0ZC15-13 |

| S0ZC15-05 | Actuator Only | 5301 | 2945 | 0.87 | 1.57 | 5301 | 2945 | 22.59 | 8000 | 3.74 | 0.748 | S0ZC15-13 |

| S0ZC15-07 | Actuator Only | 5301 | 2945 | 1.43 | 2.57 | 5301 | 2945 | 37.12 | 5000 | 3.74 | 0.748 | S0ZC15-13 |

| S0ZC15-11 | Actuator Only | 5301 | 2945 | 2.3 | 4.14 | 5301 | 2945 | 59.71 | 5000 | 3.74 | 0.748 | S0ZC15-13 |

| S0ZC15-13 | Actuator Only | 4591 | 2550 | 3.54 | 6.38 | 5301 | 2945 | 79.66 | 5000 | 3.74 | 0.748 | S0ZC15-13 |

| S0ZC15-21 | Actuator Only | 5301 | 2945 | 4.04 | 7.27 | 5301 | 2945 | 104.89 | 5000 | 7.48 | 1.496 | S0ZC15-36 |

| S0ZC15-23 | Actuator Only | 5301 | 2945 | 4.85 | 8.73 | 5301 | 2945 | 125.87 | 5000 | 7.48 | 1.496 | S0ZC15-36 |

| S0ZC15-27 | Actuator Only | 5301 | 2945 | 6.46 | 11.64 | 5301 | 2945 | 167.83 | 5000 | 7.48 | 1.496 | S0ZC15-36 |

| S0ZC15-31 | Actuator Only | 5301 | 2945 | 9.09 | 16.36 | 5301 | 2945 | 236.01 | 4000 | 7.48 | 1.496 | S0ZC15-36 |

| S0ZC15-34 | Actuator Only | 5301 | 2945 | 11.72 | 21.09 | 5301 | 2945 | 304.19 | 4000 | 7.48 | 1.496 | S0ZC15-36 |

| S0ZC15-36 | Actuator Only | 4473 | 2485 | 15.35 | 27.64 | 5301 | 2945 | 336.33 | 3000 | 7.48 | 1.496 | S0ZC15-36 |

| S0ZC20-02 | Actuator Only | 9424 | 7068 | 0.21 | 0.28 | 9425 | 7069 | 9.68 | 8000 | 3.74 | 0.748 | S0ZC20-13 |

| S0ZC20-05 | Actuator Only | 9424 | 7068 | 0.49 | 0.65 | 9425 | 7069 | 22.59 | 8000 | 3.74 | 0.748 | S0ZC20-13 |

| S0ZC20-07 | Actuator Only | 9424 | 7068 | 0.8 | 1.07 | 9425 | 7069 | 37.12 | 5000 | 3.74 | 0.748 | S0ZC20-13 |

| S0ZC20-11 | Actuator Only | 9424 | 7068 | 1.29 | 1.72 | 9425 | 7069 | 59.71 | 5000 | 3.74 | 0.748 | S0ZC20-13 |

| S0ZC20-13 | Actuator Only | 8161 | 6121 | 1.99 | 2.66 | 9425 | 7069 | 79.66 | 5000 | 3.74 | 0.748 | S0ZC20-13 |

| S0ZC20-21 | Actuator Only | 9424 | 7068 | 2.27 | 3.03 | 9425 | 7069 | 104.89 | 5000 | 7.48 | 1.496 | S0ZC20-36 |

| S0ZC20-23 | Actuator Only | 9424 | 7068 | 2.73 | 3.64 | 9425 | 7069 | 125.87 | 5000 | 7.48 | 1.496 | S0ZC20-36 |

| S0ZC20-27 | Actuator Only | 9424 | 7068 | 3.64 | 4.85 | 9425 | 7069 | 167.83 | 5000 | 7.48 | 1.496 | S0ZC20-36 |

| S0ZC20-31 | Actuator Only | 9424 | 7068 | 5.11 | 6.82 | 9425 | 7069 | 236.01 | 4000 | 7.48 | 1.496 | S0ZC20-36 |

| S0ZC20-34 | Actuator Only | 9424 | 7068 | 6.59 | 8.79 | 9425 | 7069 | 304.19 | 4000 | 7.48 | 1.496 | S0ZC20-36 |

| S0ZC20-36 | Actuator Only | 7952 | 5964 | 8.64 | 11.51 | 9425 | 7069 | 336.33 | 3000 | 7.48 | 1.496 | S0ZC20-36 |

| S0ZC25-02 | Actuator Only | 14726 | 10271 | 0.13 | 0.19 | 14726 | 10272 | 9.68 | 8000 | 3.74 | 0.748 | S0ZC25-13 |

| S0ZC25-05 | Actuator Only | 14726 | 10271 | 0.31 | 0.45 | 14726 | 10272 | 22.59 | 8000 | 3.74 | 0.748 | S0ZC25-13 |

| S0ZC25-07 | Actuator Only | 14726 | 10271 | 0.51 | 0.74 | 14726 | 10272 | 37.12 | 5000 | 3.74 | 0.748 | S0ZC25-13 |

| S0ZC25-11 | Actuator Only | 14726 | 10271 | 0.83 | 1.19 | 14726 | 10272 | 59.71 | 5000 | 3.74 | 0.748 | S0ZC25-13 |

| S0ZC25-13 | Actuator Only | 12752 | 8895 | 1.28 | 1.83 | 14726 | 10272 | 79.66 | 5000 | 3.74 | 0.748 | S0ZC25-13 |

| S0ZC25-21 | Actuator Only | 14726 | 10271 | 1.45 | 2.09 | 14726 | 10272 | 104.89 | 5000 | 7.48 | 1.496 | S0ZC25-36 |

| S0ZC25-23 | Actuator Only | 14726 | 10271 | 1.75 | 2.5 | 14726 | 10272 | 125.87 | 5000 | 7.48 | 1.496 | S0ZC25-36 |

| S0ZC25-27 | Actuator Only | 14726 | 10271 | 2.33 | 3.34 | 14726 | 10272 | 167.83 | 5000 | 7.48 | 1.496 | S0ZC25-36 |

| S0ZC25-31 | Actuator Only | 14726 | 10271 | 3.27 | 4.69 | 14726 | 10272 | 236.01 | 4000 | 7.48 | 1.496 | S0ZC25-36 |

| S0ZC25-34 | Actuator Only | 14726 | 10271 | 4.22 | 6.05 | 14726 | 10272 | 304.19 | 4000 | 7.48 | 1.496 | S0ZC25-36 |

| S0ZC25-36 | Actuator Only | 12425 | 8667 | 5.53 | 7.92 | 14726 | 10272 | 336.33 | 3000 | 7.48 | 1.496 | S0ZC25-36 |

| S0ZC32-02 | Actuator Only | 24887 | 20432 | 0.08 | 0.1 | 24887 | 20433 | 9.68 | 8000 | 3.74 | 0.748 | S0ZC32-13 |

| S0ZC32-05 | Actuator Only | 24887 | 20432 | 0.19 | 0.23 | 24887 | 20433 | 22.59 | 8000 | 3.74 | 0.748 | S0ZC32-13 |

| S0ZC32-07 | Actuator Only | 24887 | 20432 | 0.3 | 0.37 | 24887 | 20433 | 37.12 | 5000 | 3.74 | 0.748 | S0ZC32-13 |

| S0ZC32-11 | Actuator Only | 24887 | 20432 | 0.49 | 0.6 | 24887 | 20433 | 59.71 | 5000 | 3.74 | 0.748 | S0ZC32-13 |

| S0ZC32-13 | Actuator Only | 21552 | 17694 | 0.75 | 0.92 | 24887 | 20433 | 79.66 | 5000 | 3.74 | 0.748 | S0ZC32-13 |

| S0ZC32-21 | Actuator Only | 24887 | 20432 | 0.86 | 1.05 | 24887 | 20433 | 104.89 | 5000 | 7.48 | 1.496 | S0ZC32-36 |

| S0ZC32-23 | Actuator Only | 24887 | 20432 | 1.03 | 1.26 | 24887 | 20433 | 125.87 | 5000 | 7.48 | 1.496 | S0ZC32-36 |

| S0ZC32-27 | Actuator Only | 24887 | 20432 | 1.38 | 1.68 | 24887 | 20433 | 167.83 | 5000 | 7.48 | 1.496 | S0ZC32-36 |

| S0ZC32-31 | Actuator Only | 24887 | 20432 | 1.94 | 2.36 | 24887 | 20433 | 236.01 | 4000 | 7.48 | 1.496 | S0ZC32-36 |

| S0ZC32-34 | Actuator Only | 24887 | 20432 | 2.5 | 3.04 | 24887 | 20433 | 304.19 | 4000 | 7.48 | 1.496 | S0ZC32-36 |

| S0ZC32-36 | Actuator Only | 20999 | 17240 | 3.27 | 3.98 | 24887 | 20433 | 336.33 | 3000 | 7.48 | 1.496 | S0ZC32-36 |

| S0ZC40-02 | Actuator Only | 37699 | 28274 | 0.05 | 0.07 | 37699 | 28274 | 9.68 | 8000 | 3.74 | 0.748 | S0ZC40-13 |

| S0ZC40-05 | Actuator Only | 37699 | 28274 | 0.12 | 0.16 | 37699 | 28274 | 22.59 | 8000 | 3.74 | 0.748 | S0ZC40-13 |

| S0ZC40-07 | Actuator Only | 37699 | 28274 | 0.2 | 0.27 | 37699 | 28274 | 37.12 | 5000 | 3.74 | 0.748 | S0ZC40-13 |

| S0ZC40-11 | Actuator Only | 37699 | 28274 | 0.32 | 0.43 | 37699 | 28274 | 59.71 | 5000 | 3.74 | 0.748 | S0ZC40-13 |

| S0ZC40-13 | Actuator Only | 32647 | 24485 | 0.5 | 0.66 | 37699 | 28274 | 79.66 | 5000 | 3.74 | 0.748 | S0ZC40-13 |

| S0ZC40-21 | Actuator Only | 37699 | 28274 | 0.57 | 0.76 | 37699 | 28274 | 104.89 | 5000 | 7.48 | 1.496 | S0ZC40-36 |

| S0ZC40-23 | Actuator Only | 37699 | 28274 | 0.68 | 0.91 | 37699 | 28274 | 125.87 | 5000 | 7.48 | 1.496 | S0ZC40-36 |

| S0ZC40-27 | Actuator Only | 37699 | 28274 | 0.91 | 1.21 | 37699 | 28274 | 167.83 | 5000 | 7.48 | 1.496 | S0ZC40-36 |

| S0ZC40-31 | Actuator Only | 37699 | 28274 | 1.28 | 1.7 | 37699 | 28274 | 236.01 | 4000 | 7.48 | 1.496 | S0ZC40-36 |

| S0ZC40-34 | Actuator Only | 37699 | 28274 | 1.65 | 2.2 | 37699 | 28274 | 304.19 | 4000 | 7.48 | 1.496 | S0ZC40-36 |

| S0ZC40-36 | Actuator Only | 31810 | 23857 | 2.16 | 2.88 | 37699 | 28274 | 336.33 | 3000 | 7.48 | 1.496 | S0ZC40-36 |

| S0ZC50-02 | Actuator Only | 58904 | 37699 | 0.03 | 0.05 | 58905 | 37699 | 9.68 | 8000 | 3.74 | 0.748 | S0ZC50-13 |

| S0ZC50-05 | Actuator Only | 58904 | 37699 | 0.08 | 0.12 | 58905 | 37699 | 22.59 | 8000 | 3.74 | 0.748 | S0ZC50-13 |

| S0ZC50-07 | Actuator Only | 58904 | 37699 | 0.13 | 0.2 | 58905 | 37699 | 37.12 | 5000 | 3.74 | 0.748 | S0ZC50-13 |

| S0ZC50-11 | Actuator Only | 58904 | 37699 | 0.21 | 0.32 | 58905 | 37699 | 59.71 | 5000 | 3.74 | 0.748 | S0ZC50-13 |

| S0ZC50-13 | Actuator Only | 51011 | 32647 | 0.32 | 0.5 | 58905 | 37699 | 79.66 | 5000 | 3.74 | 0.748 | S0ZC50-13 |

| S0ZC50-21 | Actuator Only | 58904 | 37699 | 0.36 | 0.57 | 58905 | 37699 | 104.89 | 5000 | 7.48 | 1.496 | S0ZC50-13 |

| S0ZC50-23 | Actuator Only | 58904 | 37699 | 0.44 | 0.68 | 58905 | 37699 | 125.87 | 5000 | 7.48 | 1.496 | S0ZC50-36 |

| S0ZC50-27 | Actuator Only | 58904 | 37699 | 0.58 | 0.91 | 58905 | 37699 | 167.83 | 5000 | 7.48 | 1.496 | S0ZC50-36 |

| S0ZC50-31 | Actuator Only | 58904 | 37699 | 0.82 | 1.28 | 58905 | 37699 | 236.01 | 4000 | 7.48 | 1.496 | S0ZC50-36 |

| S0ZC50-34 | Actuator Only | 58904 | 37699 | 1.05 | 1.65 | 58905 | 37699 | 304.19 | 4000 | 7.48 | 1.496 | S0ZC50-36 |

| S0ZC50-36 | Actuator Only | 49703 | 31810 | 1.38 | 2.16 | 58905 | 37699 | 336.33 | 3000 | 7.48 | 1.496 | S0ZC50-36 |

| S0ZC60-02 | Actuator Only | 84823 | 55959 | 0.02 | 0.04 | 84823 | 55960 | 9.68 | 8000 | 3.74 | 0.748 | S0ZC60-13 |

| S0ZC60-05 | Actuator Only | 84823 | 55959 | 0.05 | 0.08 | 84823 | 55960 | 22.59 | 8000 | 3.74 | 0.748 | S0ZC60-13 |

| S0ZC60-07 | Actuator Only | 84823 | 55959 | 0.09 | 0.14 | 84823 | 55960 | 37.12 | 5000 | 3.74 | 0.748 | S0ZC60-13 |

| S0ZC60-11 | Actuator Only | 84823 | 55959 | 0.14 | 0.22 | 84823 | 55960 | 59.71 | 5000 | 3.74 | 0.748 | S0ZC60-13 |

| S0ZC60-13 | Actuator Only | 73456 | 48461 | 0.22 | 0.34 | 84823 | 55960 | 79.66 | 5000 | 3.74 | 0.748 | S0ZC60-13 |

| S0ZC60-21 | Actuator Only | 84823 | 55959 | 0.25 | 0.38 | 84823 | 55960 | 104.89 | 5000 | 7.48 | 1.496 | S0ZC60-36 |

| S0ZC60-23 | Actuator Only | 84823 | 55959 | 0.3 | 0.46 | 84823 | 55960 | 125.87 | 5000 | 7.48 | 1.496 | S0ZC60-36 |

| S0ZC60-27 | Actuator Only | 84823 | 55959 | 0.4 | 0.61 | 84823 | 55960 | 167.83 | 5000 | 7.48 | 1.496 | S0ZC60-36 |

| S0ZC60-31 | Actuator Only | 84823 | 55959 | 0.57 | 0.86 | 84823 | 55960 | 236.01 | 4000 | 7.48 | 1.496 | S0ZC60-36 |

| S0ZC60-34 | Actuator Only | 84823 | 55959 | 0.73 | 1.11 | 84823 | 55960 | 304.19 | 4000 | 7.48 | 1.496 | S0ZC60-36 |

| S0ZC60-36 | Actuator Only | 71573 | 47218 | 0.96 | 1.45 | 84823 | 55960 | 336.33 | 3000 | 7.48 | 1.496 | S0ZC60-36 |

| S0ZC80-02 | Actuator Only | 150796 | 113097 | 0.01 | 0.02 | 150796 | 113097 | 9.68 | 8000 | 3.74 | 0.748 | S0ZC80-13 |

| S0ZC80-05 | Actuator Only | 150796 | 113097 | 0.03 | 0.04 | 150796 | 113097 | 22.59 | 8000 | 3.74 | 0.748 | S0ZC80-13 |

| S0ZC80-07 | Actuator Only | 150796 | 113097 | 0.05 | 0.07 | 150796 | 113097 | 37.12 | 5000 | 3.74 | 0.748 | S0ZC80-13 |

| S0ZC80-11 | Actuator Only | 150796 | 113097 | 0.08 | 0.11 | 150796 | 113097 | 59.71 | 5000 | 3.74 | 0.748 | S0ZC80-13 |

| S0ZC80-13 | Actuator Only | 130589 | 97942 | 0.12 | 0.17 | 150796 | 113097 | 79.66 | 5000 | 3.74 | 0.748 | S0ZC80-13 |

| S0ZC80-21 | Actuator Only | 150796 | 113097 | 0.14 | 0.19 | 150796 | 113097 | 104.89 | 5000 | 7.48 | 1.496 | S0ZC80-36 |

| S0ZC80-23 | Actuator Only | 150796 | 113097 | 0.17 | 0.23 | 150796 | 113097 | 125.87 | 5000 | 7.48 | 1.496 | S0ZC80-36 |

| S0ZC80-27 | Actuator Only | 150796 | 113097 | 0.23 | 0.3 | 150796 | 113097 | 167.83 | 5000 | 7.48 | 1.496 | S0ZC80-36 |

| S0ZC80-31 | Actuator Only | 150796 | 113097 | 0.32 | 0.43 | 150796 | 113097 | 236.01 | 4000 | 7.48 | 1.496 | S0ZC80-36 |

| S0ZC80-34 | Actuator Only | 150796 | 113097 | 0.41 | 0.55 | 150796 | 113097 | 304.19 | 4000 | 7.48 | 1.496 | S0ZC80-36 |

| S0ZC80-36 | Actuator Only | 127241 | 95430 | 0.54 | 0.72 | 150796 | 113097 | 336.33 | 3000 | 7.48 | 1.496 | S0ZC80-36 |